|

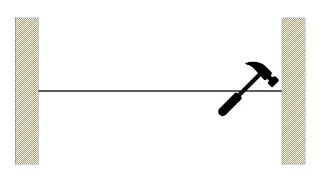

| Picture a piano string in your head. A hammer thumps it |

|

| And the string deflects. Because of the interactions between the mass and the springiness, the string vibrates. |

|

| If the hammer hits the string where it cannot move then no energy is transmitted to the string. Work = energy = force * distance. If distance = zero, then energy is zero. |

|

| An even simpler conceptualization of a vibrating system |

|

| If the forcing function is a quick impulse (momentum deposition) then the system is mass dominated. Mass goes up in proportion to T. |

Damping is energy dissipation.

Most commercial solutions involve adding damping. They work well for excitations like electric motors where the forcing functions are continuous. Without damping, the oscillations grow and the noise level is obnoxious. With damping, the oscillations never grow and the noise levels never grow to unacceptable levels.

Adding damping is less dramatic for impulse excitations. The peak level attenuates quickly but the peak level is not much lower than it would be without the damping.

BUT....

Data rules.

Let's have a horse race.

I think the winner will be increasing the thickness of the cap. Increasing the thickness of the cap both increases the stiffness and the mass where the impact occurs. I can also sneak in a little bit of damping if I put slug of steel inside the driver and sandwich a tiny bit of butyl rubber between the slug and the end-cap of the driver.

But I will give the other proposals a shot if I can fab them up.

If you have access to a welding machine, weld about a 10" black pipe extension to top of the driver barrel and fill it with lead shot.

ReplyDelete(Sorry, read this post before the preceding one. Adding oil to the shot is a good idea too and if you use a black iron nipple you can add a threaded cap).

ReplyDeleteWhy add oil?

DeleteI think it is to provide viscous damping and to prevent the steel shot from rusting into a solid mass.

DeleteAnd it will keep lead shot from sticking together.

DeleteAnd thinking how this might apply to an economy and protests . . . .

ReplyDeleteI'm thinking about the kinetic energy portion.

ReplyDeleteWould it be better to have a somewhat longer driver of the same weight so that you could increase the downward speed of the driver and get a bit more bang for the effort?

I took a short side trip to the internet and found there are a number of air powered post drivers.

Maybe there's a viable rental option depending on the number of posts that you have to drive.

The best solution involves utilizing someone else's sweat... Fencing is that kind of work that makes a farmer or rancher start talking to themself.

ReplyDeleteFortunately, I am good company.

Delete