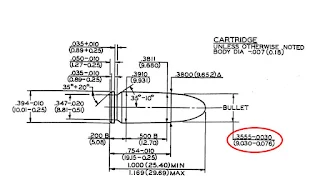

For one thing, the maximum bullet size listed in the drawings is 0.3555" in diameter. Think of it as a peg.

|

Will a 0.3555" peg fit in a 0.354" hole? The answer is "Not easily"

Why have you never heard of this problem? Because the major manufactures of defensive firearms are not stupid. The SAAMI chambers are MINIMUM allowable chambers. The majors bore the throat a little bit long and a little bit larger diameter. Consequently, a Glock or an S&W will feed and fire a wide range of ammo without a hiccup.

One of the neighbors came over with a new handgun. We have a large pit we use for the purpose of test firing handguns.

The firearm was a Taurus G2. It fed the FMJ ammo just fine.

It coughed up a hairball on the 9mm hollow-points. I pulled out a digital caliper and the COAL was 1.125" which complies with SAAMI specs.

So the neighbor's handgun either has a bur in the chamber, machining marks or it is at a true, SAAMI minimum.

Can any of my readers advise regarding difficulty of polishing the throat of the chamber? Are there inexpensive tools (like pencil eraser and jeweler's rouge) that will work?

I cannot imagine that I will need to polish out more than 0.002" to make this a happy-happy gun.

I don't want to tell the neighbor to send the gun back to Taurus. The chamber is probably within spec.

I recall having to polish the ramp with jewelers rouge on my P238 because of its short geometry as one person put it. It is possible that the move kept valuable momentum from being expended. Yeah, 380 and you are talking 9mm but it is the same diameter.

ReplyDeleteSend it back to taurus.

ReplyDeleteMcgyver gusmithing will void any warranty (if it is new) and often makes the problem worse.

IIRC, Taurus has a lifetime warranty.

Since the handgun has shown sensitivity to ammo, the quickest solution will be to try several different brands of defensive ammo. Gold-Dots are next on the list.

DeleteAnd now you know why I use Glocks. Seriously, send it back to Taurus. They will fix it for free and it will never fail you again. With ANY Taurus, run 200 rounds through it as soon as you get it. If it is going to fail, it will then.

ReplyDeleteYou may be overthinking this one. Will it go into battery if the round is dropped into the chamber with the mag removed? (Yeah, I know it's not good for extractor to do this). I suspect the hps are feeding out of the mag at a different angle than the folks.

ReplyDeleteFmjs, not folks. Darn autocorrect.

ReplyDeleteFirst, YMMV depending on skills and tools.

ReplyDeleteSecond, voiding the warranty is a valid consideration.

I have a Henry .22 that had to be cycled 'crisply' or 'vigorously' to feed properly. I fully disassembled the action and laid it on my towel. I used various drill bits and flat stock as sanding blocks and 3000 or 4000 grit wet sandpaper to polish all the contact points and sliding parts.

Patience was critical and extremely difficult for me...

But it smoothed the action considerably. No more misfeeds and it cycles smoothly and consistently.

Again, YMMV

To answer your question.

ReplyDeleteI checked the Brownells website and they offer a line of hones designed to polish chambers.

https://www.brownells.com/gunsmith-tools-supplies/handgun-tools/hones-files/cylinder-polishing-system-prod61384.aspx

This is the website for Brush Research.

http://www.brushresearch.com/

Amazon has some Brush Research hones listed.

This is for 9mm.

https://smile.amazon.com/Research-08309-Revolver-Chamber-Flex-Hone/dp/B00DB8DZ2I/ref=sr_1_1?dchild=1&keywords=pistol+chamber+hone&qid=1592657459&sr=8-1

You can consider using a bore mop and charge it with abrasive compound.

Or use the appropriate sized fine brush, and wrap the brush in a patch that you've charged with abrasive compound.

(I figure you know this) Use a rapid back and forth motion while spinning your tool with a drill.

Although this isn't answering your question, have you considered running the problem ammunition lightly into a resizing die?

I really appreciate you mentioning chamber hones. It is exactly what I needed to hear in order to get a start on clearing up a problem I have. Very valuable discussion here.

DeleteIs it not fitting the chamber (i.e. it happens when manually fed) or is it not making it up the ramp from the magazine?

ReplyDeleteSome guns are very picky with hollowpoints - does it do it with all hollowpoints, or just certain brands?

I have a Kimber ultra carry in .45 that was bad about chambering a new round. Resolution was 2 step. First I polished the feed ramp then the chamber, focussing on the top of the chamber as I assumed there would be more contact by the nose of the bullet. Second I found a hollow point that worked better. In this case I found remington golden sabres worked best as the shape of the projectile more closely resembled ball. For polishing the ramp and chamber I used some jewelers rouge on a hard round mop spun by a dremel tool.

ReplyDelete