|

| A 3" long 5/16" diameter bolt with the threads on the end half filed off. In the future I will use a four or five inch bolt. |

|

| Jaws of the vice spread far enough to allow the primer to move downward but close enough to support the base of the hull. |

|

| This is what it looks like after a tap with a hammer. |

|

| Then the removal of the primer is completed using the claw of the hammer. |

|

| Viola! |

New primer installed

|

| Primers are taken out of the box and spread out with the fat ends down. The hull is placed over the primer and pressed down to partially insert the primer. |

|

| The jaws of the vice are not gripping the body of the hull. They are spaced so they catch the rim of the hull. |

|

| A flat bar is placed over the primer and used to seat the primer. The bar is tilted slightly in this photo so you can see the primer. |

|

| Seated primer should look like this. |

Refilling the shell

|

| Here is the tool set for refilling the shell. This is about the amount of table space you will need to get the job done. |

|

| Kubota donated an empty Dr Pepper can to the project. This is a simple spiral of aluminum sheet that can be manipulated to form a funnel. |

|

| Here it is squeezed down to show that the small end can be varied in size. |

|

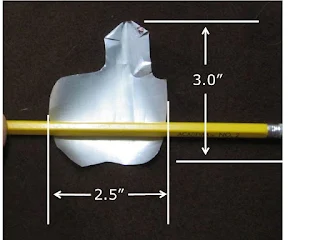

| The funnel went through a bit of trimming and tweaking. This is what the funnel looked like at the end of the project. It does not take much material! |

|

| The lack of three hands resulted in this awkward shot of the powder being dumped into the hull. Rest assured that the small end of the funnel is in the mouth of the hull. |

|

| Sending the wad. This is the most difficult part of the enterprise. I found that it worked best when the mouth of the funnel was just barely inside the mouth of the hull. |

|

| The hull installs easily after it is started. |

|

| 2.6cc of #6 shot weighed 0.5 ounces. Things are so small and fiddly that I needed to remove two pellets before I could get a decent crimp. |

Finished goods

|

| Making the crimp is a fiddly bit of work. I ended up reversing my pocket knife and pressing in the folds in six places in multiple passes. This is a place where I need a better tool. |

Tools used

- Bench vice

- A 5/16" bolt with modified threads

- Claw hammer

- Table top

- Flat piece of steel

- Small piece of aluminum from a beverage can

- A custom powder measure made from the casing of a fired cartridge and a paper clip

- A couple of plastic containers to hold smokeless powder and shot

- A 1.3cc, Lee dipper

- A pocket knife

Did they load and shoot?

ReplyDeleteMy 20GA & 12GA reloads demand re-sized brass to chamber.