|

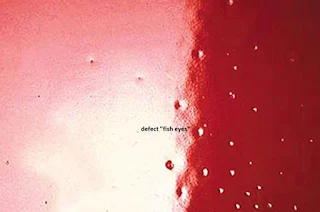

| Contamination is a frequent cause of fish-eyes and craters in paint. Some classes of dirt (antiperspirant is notorious for this) repel the paint film and it will not level around the dirt. |

Do you see the engine? Nope, that is beneath the hood.

Do you see the radio or the seats? Nope, those are inside the car.

Do you see the bare metal? Nope. You cannot tell if it is galvanized or bare, thin or thick.

Most of what you see is paint.

History

I used to work in the automotive industry. I was blessed to work in all four shops: Metal Stamping, Body, Paint and Final Assembly.

Each of the shops have their own culture and language.

The Paint Shop, for instance, operates in a clean-room environment. The number one defect, by count, in Paint is "dirt". That category dwarfs all others if you include all forms of paint film contamination.

A sixty-job an hour production line might have twenty people per shift dedicated to repairing paint defects and the majority of those defects are "dirt". Obviously, there is big money at stake.

Big money!

Every new hire in the North American, unionized, automotive environment can be looked at as a $5 million commitment: Pay for thirty years, benefits for life.

Twenty warm bodies, three-shifts, $5m per equals $300m and that does not include the investment in floor space, equipment and utilities.

That $300m does not include the warranty costs where dealerships see and repair paint defects, nor does it include the cost of sales lost because the customer chose a different product.

What does that have to do with packing your own parachute?

I want to call attention to three features I noticed in the last automotive Paint Shop I worked in. I won't mention any names because it should be acutely embarrassing to them.

Personal Protective Equipment

To enter the Paint Shop clean-room you have to don a polyester monkey suit. A very specific, non-fiber shedding set of gloves is mandatory.

Booties are NOT mandatory. Take about five seconds and think about which articles of apparel carry the most dirt. Your shirt? Your trousers? Your socks? Nope. As a general rule, none of them touch the ground (dirt) on a regular basis. The answer is "Your footwear". But no booties? What the heck.

Airlocks

The next thing you notice is that you walk through an semi-airlock and have to stand under a room sized blower reminiscent of the one in the Men's room at MacDonalds. Oh, and it is about as loud.

The first few times you go through this room you won't notice that the steel grating used for flooring does not have a plenum beneath it. That is, the high speed blast of air does not flow down from the ceiling, wash over dirty, despicable you and thence into the floor->ducting->filters->outside.

Nope, it scrubs the dirt and dust off of you (hair, outside of monkey suit, clip board, lunch bucket, etc) and blasts it out into the clean room. You see, it is only half of an airlock. There is an air-tight door separating the air-blast (and noise) from the office area but it is open to the paint clean-room.

When I pointed out the absurdity of this to the boss, he rolled his eyes and stated "Paint HQ did a study and most of the dust falls to the ground and is trapped in the steel grating."

Yeah, right. Most by weight? How can you know how much is actually being blown off the people coming in. Oh, and how do you clean out the grating without blasting a significant portion of that dirt back into the air?

I suspect that they were able to wring quite a bit of cost out of the building by not having to include ducting and by being able to down-size the fans needed to keep the clean-room positive pressure. Somebody was a hero for penciling $5m out of the cost of the construction.

Where do you keep your armies?

In your sleevies, of course.

The final thing you are likely to notice is that the monkey suit does not have elastic sleeves, nor does management require that operators keep the sleeves snapped tight.

|

| Image of lint and dander flowing out of the end of a sleeve and onto a surface about to be painted. |

So an operator can be wearing a shirt that is shedding lint like a German Shepherd in April and the un-snapped sleeves guarantee that the lint will pour out of the sleeves at the wrist land on the tops of fenders, hood, deck-lid and roof of the vehicle.

Still not clear on why I pack my own parachute?

The Paint Shop is an example from the profit motivated, private sector where highly-trained management at all levels failed to take the simplest, most fundamental steps to contain contamination.

Not only did they fail to contain contamination: THEY MADE IT WORSE!

If a highly motivated, private sector company cannot pull its head out of its nether region and take SIMPLE, EFFECTIVE steps to control visible contamination, why would I trust untrained, public-sector organizations to do better at "managing" the invisible Corona virus?

Intentions are not enough. The air-blast was designed with good intentions.

Results matter.

They are counting on people 'accepting' lower quality... sigh

ReplyDeleteIdiots all the way down.

ReplyDeleteTheir decisions are idiotic but the reason is not because they are idiots but because they are trapped in the "sunk costs" trap.

DeleteSunk costs will probably be the topic of a future post.

(quietly hides duct tape)

ReplyDelete