Welded joints

MIG welding (aka, wire welding, gas metal arc welding) makes it possible for craftsmen who are part time welders to make high quality, good looking welds. The equipment and consumables are relatively inexpensive. The process is quick. The technique required is within the reach of most people who have the ability to tie their shoes or can reliably hit the bristles of their toothbrush with a bead of toothpaste.

I want to share a few tips that will help welders produce more durable welds.

The three Ps: Penetration, penetration penetration.

The cardinal sin of MIG welding is inadequate penetration. It is possible to produce a cosmetically beautiful weld with unacceptable amounts of cold lap. Errors of excessive penetration are self announcing and self correcting.

Usually, the best solution to excessive penetration is to back-up the work with a heat sink. A heat sink needs to be no fanciner than a very rusty piece of steel plate that is held 0.10 inches (2.5mm) away from the back of the work piece.

To increase penetration:

- Increase wire speed. Penetration on mild steel increases up to a wire speed of about 200 inches per minute.

- Decrease voltage. Decreasing the voltage reduces the "fanning" diameter. That is, the weld bead is narrower. The power is deposited over a smaller area and digs more deeply.

- Reduce stick-out. Choke up on the puddle. Conversely, at the end of the weld bead when you are trying to fill the crater without blowing through the metal, you probably want to increase stick-out.

- Increasing the wire diameter. Your equipment will have limitations but increasing wire diameter to the largest your equipment will handle will increase penetration.

- Reorient the weld so it is vertical and the direction of travel is upward. Discussed later in this essay.

Fillet welds:

Fillet welds are probably the most common type of weld for the home hobbiest. They are typically used to attached "hard points" to structures. These hardpoints are places where concentrated loads are applied. Brackets, shackles, hooks, cleats and pads are typical "hard points" They are usually made of materials that are thicker than the base material. |

| The jargon. Find the toe of the weld. We will be talking about it later. |

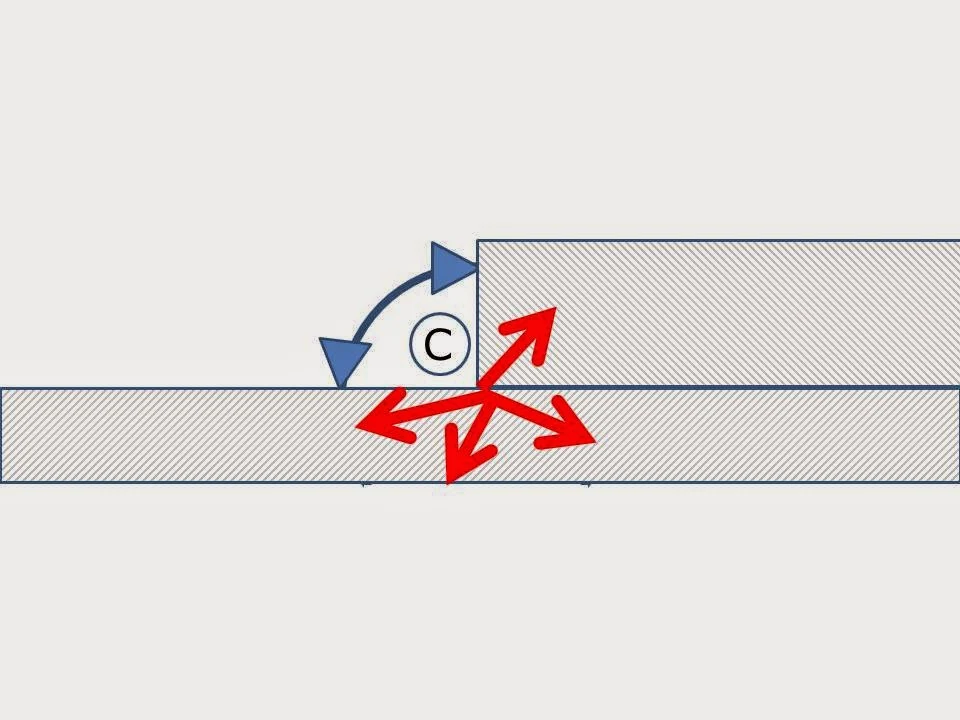

Fusion typically first occurs at area A because there is less metal mass absorbing the heat of the arc. It heats up more quickly and the corner melts. An additional factor is that sharp edges attract arc. That is why lightening rods are pointy and the business end of spark plugs have crisp corners.

|

| Red arrows illustrating that 90 degrees of metal are wicking heat away from corner. Fusion (penetration) first occurs at area A |

|

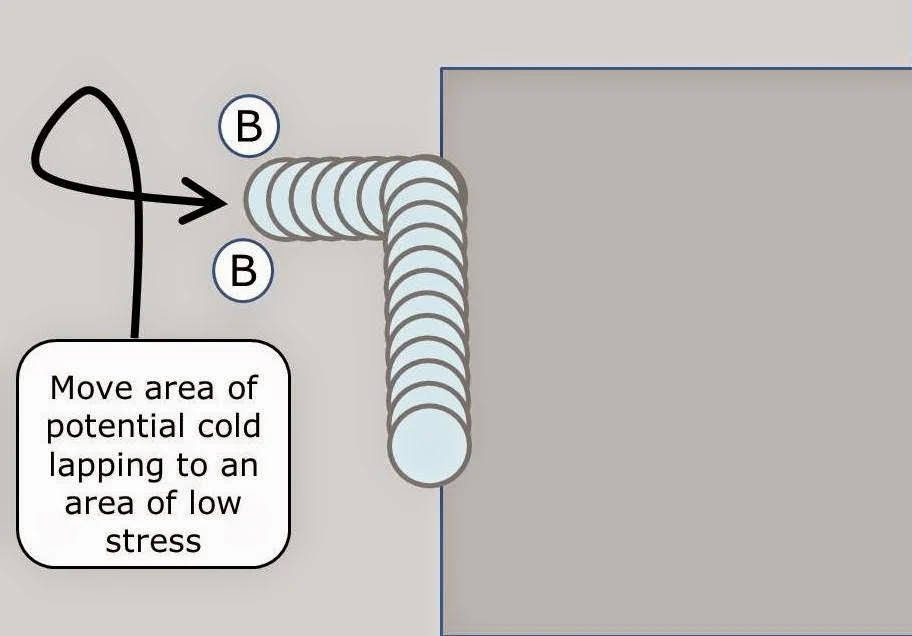

| Area B is more vulnerable to lack of fusion than area A because there is 180 degrees of metal wicking the heat away from the weld. |

The start and end are the parts of the weld where structural failures, cracks, are most likely to originate. There are several reasons for this. One reason is that the stresses are highest here even if the welds were perfect. High stresses are the result of load funneling through a limited cross section of material. All of the load from the area where the weld "skips" tries to crowd into the hard point through the start and end of the weld.

In fact, the weld quality at the start and end of the weld are rarely perfect. The start of the weld is susceptible to cold lapping, inadequate leg length and sharp toe angles. The end of the weld is vulnerable to lack of metal fill. The weld technique to ensure good crater fill at the end of the weld is easy to master, so this essay will focus on the start of the weld. Think of the start of the weld as the slider of a zipper. The zipper will not unzip if you lock the slider.

One of the first things I was taught in driver's ed was to separate hazards. Suppose you are driving and there is a car parked on your side of a narrow street. Further, suppose you have oncoming traffic. The prudent thing to do is to either speed up or slow down so you do not need to deal with both hazards at the same time, in the same space.

Most weld fab drawings have no "penalty" for extra length of weld. Starting off-the-joint puts heat into the base metal ensuring good toe angles and no cold lapping where it counts. I saw this technique used on the trailing-twist axle of a Nissan product.

Reflowing

Another technique is to reflow the weld by hitting select portions of the weld with a heat source like a TIG, plasma arc or oxy-acetylene torch.

Reflowing is the best (in many cases the only economical) way to smooth out sharp toe angles which look like blunt crack tips to the structure. The beauty of reflowing is that 90% of the benefit can be attained by reflowing the start of the weld. That is, the first 5/8" (15mm) of a typical weld bead.

Reflowing addresses the sharp toe angles that come with the high, humped up beads characteristic of weld starts. Reflowing also addresses potential cold lapping (area B) and insufficient leg length by driving fusion into area C.

Reflowing the start of the weld bead is one way of "locking the slider of the zipper" after the fact. A handy thing to know if you job the MIG welding out and just don't have a good feeling about the quality of the job that was done.

I will bookmark your site and take the feeds also.

ReplyDeleteI'm happy to seek out a lot of useful info right here within the submit we want work out extra techniques

on this regard thanks for sharing.

i have a good website about welding safety

it is here

Hi,

ReplyDeleteI have come across your blog through search and found it is really great with lost of informative welding stuff, thanks for sharing with us.

We are leading stainless steel wires manufacturers engaged in MIG Wire, TIG Wire,MIG Welding, TIG Welding

Welded joints. MIG welding (aka, wire welding, gas metal arc welding) makes it possible for craftsmen who are part time welders to make high ... welderwire.blogspot.com

ReplyDeleteI get good information after reading this blog. The content of this blog is very nice.

ReplyDeleteThanks for sharing

MIG Torch Consumables

This comment has been removed by the author.

ReplyDeleteGreat post! Thank you for the helpful tips on MIG welding.

ReplyDelete- Long Peter

Awesome and helpful post about maximizing durability of MIG welding joints. Thanks for sharing this information. Check it is for more.

ReplyDeleteHello there, I discovered your web site via Google while searching for a related topic, your web site came up, it appears good. I have bookmarked it in my google bookmarks. my sources

ReplyDeleteFillet weld is the common type of welding and it is the easiest techniques. Even I have heard about the method of plasma cutting that is new techniques for the welding. You can buy sheet metal online and weld it at home with different welding methods. Thanks for the article!

ReplyDeleteYou need to be more careful while you are working on welding side as the joint should be perfect and there should not have any hole in there as it could let the product work so perfectly in next period. At The Welding Pro you will get more information about the all kind of welding.

ReplyDeletePositive webpage, where did u think of the data on this posting?I have perused a couple of the articles on your site now, and I truly like your style. You rock and please keep up the successful work.

ReplyDeleteThank you so much for such an informative piece of information :)

ReplyDeleteIf anyone interested similar one's have a look here

besttoolsbrand

Thanks