I was resizing and depriming some brass yesterday. I have gotten pretty good at it.

Different cartridges present different challenges. Small, straight sided, rimless rounds do not offer enough tactile cues to allow sight-free orientation. I was able to use some of the training I received in my pre-retirement profession to improve the throughput of my reloading station.

Once I got going I was averaging 15 resized shells a minute with some bursts of 20 shells per minute. That is probably a bit better than average for a single stage press.

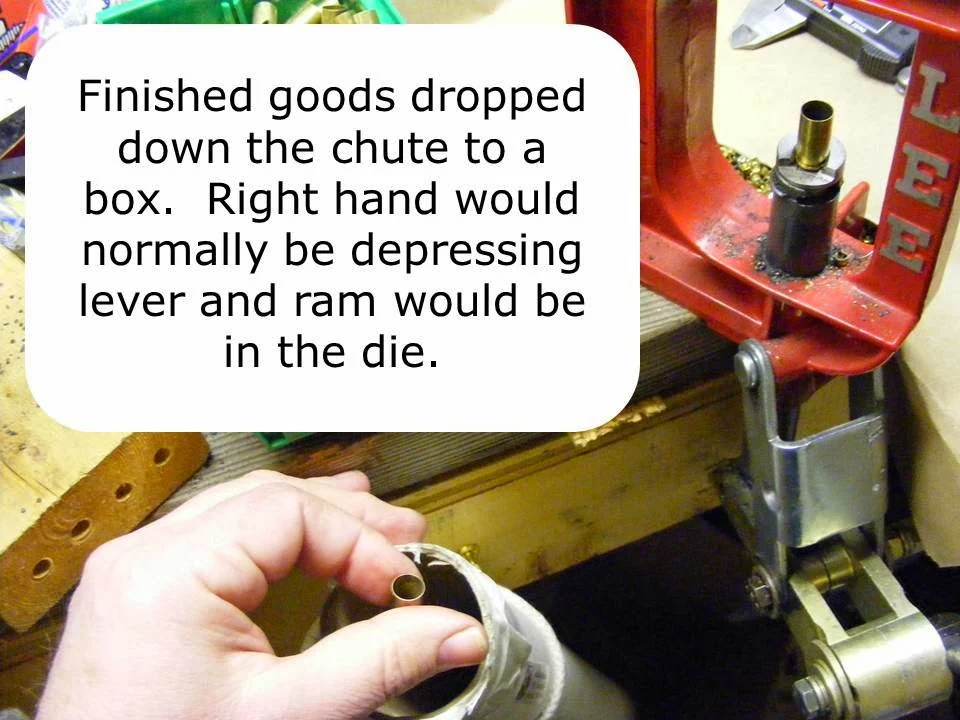

I took a few pictures to serve as thought starters for any newbies who want to speed up their production.

|

| Having stations close together means small movements. Small, smooth movements means shorter cycle times without having to rush. The triangle formed by 1-2-3 is six inches on a side. |

Obviously, putting a single layer in each bin would require more bins. I purchased my bins from Uline and have been happy with them. The bins I use are 3 inches tall by 4 inches wide by 7 inches long.

|

| Clamp the re-sized brass that is on the top of the ram between your forefinger and middle finger. |

|

| 2.3. Much of the magic for speed is in step 2.3 Crooking the middle finger rolls the resized piece off of the ram. |

I hope some of you find this helpful.

Quick and easy, and some good tips!

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDelete