This essay is a primer on Theory of Constraint.

This is your favorite Deli

|

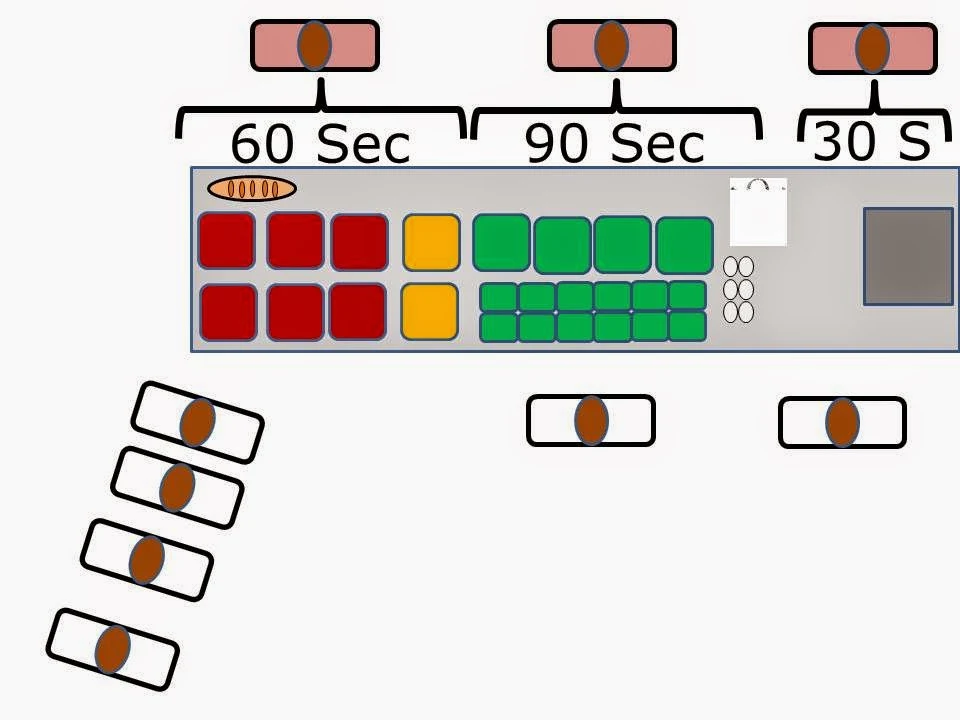

| This is a simple assembly line. It is where you buy your deli sandwich. You may have cursed how slowly it moves. |

Worker A takes the order, picks the bun and adds the meat and cheese.

Worker B adds the vegetables and condiments. Then they wrap and bag the sandwich.

Worker C pads the order with high profit add-ons like drinks, cookies and chips. They also work the cash register.

This is a case of customers will come if you "build it", throughput, that is. Customers make decisions based on the length of the line and the number of cars in the parking lot. They will go to a less-preferred restaurant if they believe the wait will be too long.

The first step is to identify any work that can be pushed to a faster station. One possibility would be to move the wrapping and bagging to Worker C. The problem is that Worker C touches money and gloving/degloving takes an excessive amount of time. From a business standpoint, Worker C can make-or-break the enterprise. Much (perhaps even most) of the profit is in up-selling the add-ons.

Each item selected takes about 10 seconds. Two seconds is consumed in communication between the customer and the worker for each item. Most customers communicate two items at a time. The worker verbally verifies and looks up to ensure they heard the order properly.

Conversations with workers indicate that a major aggravation results when customers keep asking for more items. That makes the sandwich difficult to fold and wrap. An even greater aggravation occurs when a customer wants amounts removed because the worker applied too much. Mayo is not easy to remove.

High tech solutions

For whatever reason, it is easier to identify high tech solutions to problems than it is to identify low tech solutions.

High Tech Solution #1:

|

| Cool tip: Mark the selections with a black felt tip pen (or pencil). Invert the signal so black-becomes-white on the projection TV. |

Estimated number of customers for a 90 minute lunch rush is an additional 9 customers for a 15% improvement.

High Tech Solution # 2

Install self-serve payment. Worker #3 never touches money and can leave his/her gloves on. Workers can still handle drinks/chips with gloves on. Have Worker 2 and Worker 3 rotate. They make a sandwich and handle the up-grades.

Estimated number of customers for 90 minute lunch rush is an additional 30 customers for a 50% improvement.

Low Tech Solution #1

Allow customers to buy "sticks of bread" and jump over bottleneck(s). Determine what the customer must be charged to match the average net profit, less add-ons and charge that for bread. Customer could buypass both Worker 1 and Worker 2. Worker 3 has much excess time and can use tongs to "bag" bread and walk it to the register.

The add-ons, the drinks, cookies and chips are the primary profit drivers. While it might not seem "fair" for them to cut into the line ahead of earlier customers it must be remembered that the earlier customers also had the option of buying just a stick of bread and add-ons. Ultimately, having these express customers skip Worker 2 will benefit everybody because it speeds up the line for everybody else and the express customer gets "rewarded" for not being high maintenance.

Low Tech Solution #2

One function of charging for goods is to ration them in times of scarcity. This is sometimes called "the parking meter function of money". This utility of pricing is that it rations goods that are in short supply by modifying customer behaviors.

Worker 2 can keep up with Worker 1 when they only have to deal with 2 vegetables and one condiment. It seems perfectly fair to charge for items over-and-above those three. This serves two functions. It turns higher maintenance customers into profit centers and will modify their behaviors.

Some delis offer the option of heating the sandwiches. This drives much chaos into the production line. Heated sandwiches should also be treated as a for-pay option because it makes everybody behind them wait.

Low Tech Solution #3

Add a Work-in-Process or a buffer station between Worker 1 and Worker 2. Sometimes Worker 2 gets a very simple order and can get ahead of Worker 1 but cannot capitalize on that because they are starved for their next sandwich.

Low Tech Solution #4

Upgrade the gloves so Workers 2 and 3 can track with their customer from start-of-vegetables to end-of-checkout. The super-cheap, limp, disposable gloves used in most delis take too long to don to make this a viable solution.

Low Tech Solution #5

Worker 2 should never leave their station to restock. That should all be handled by Worker 3. Worker 3 can catch up. Worker 2 never can.

No comments:

Post a Comment

Readers who are willing to comment make this a better blog. Civil dialog is a valuable thing.